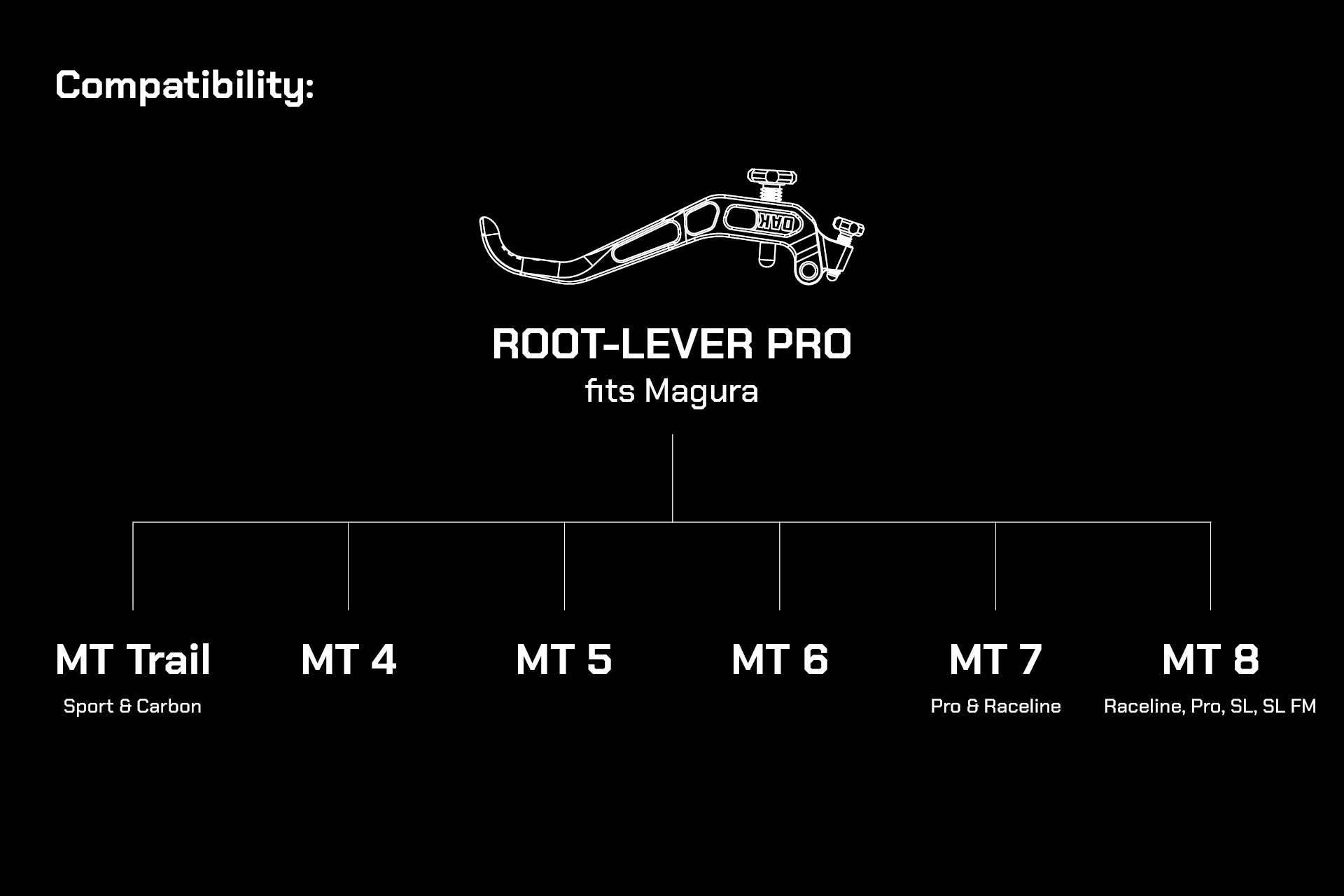

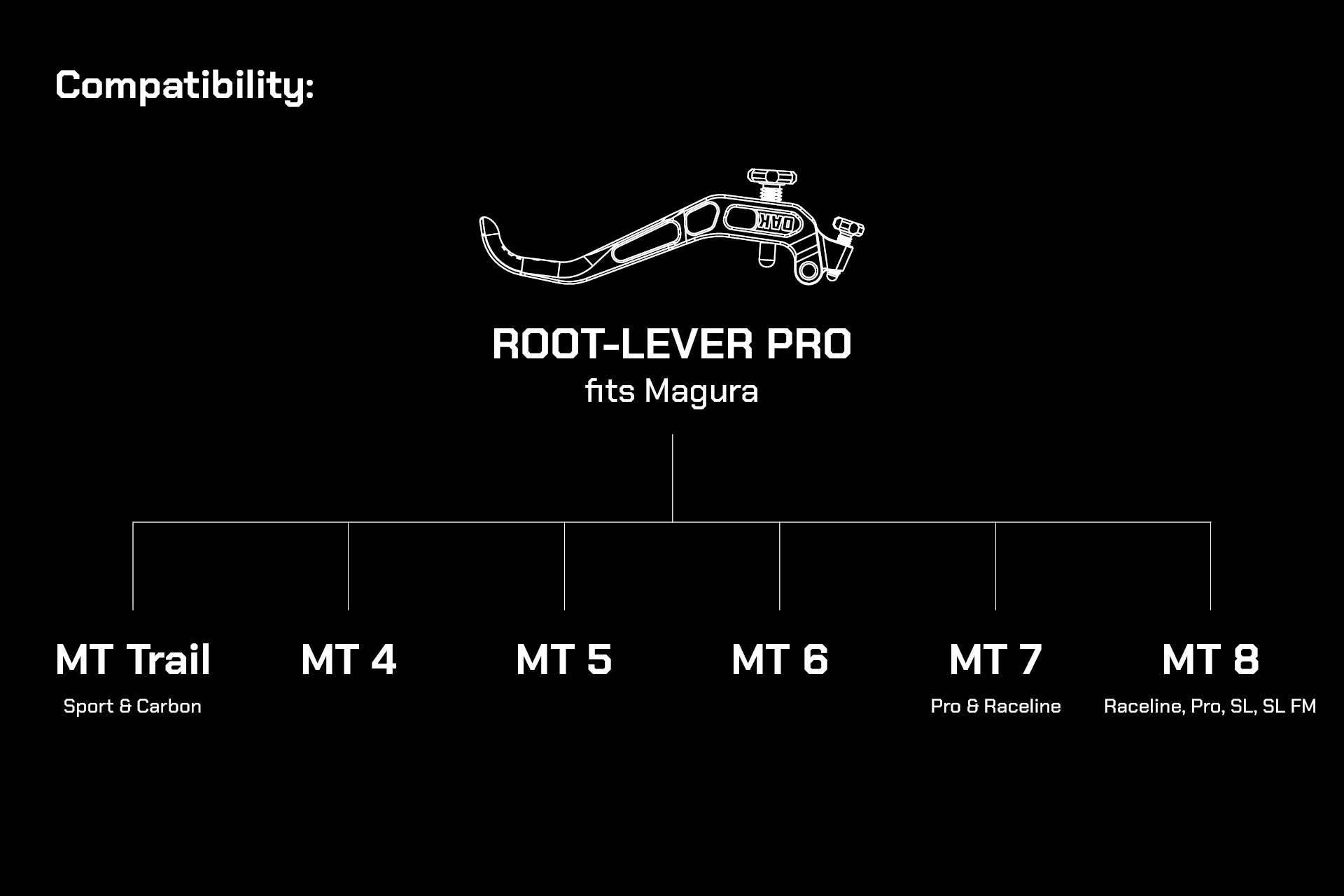

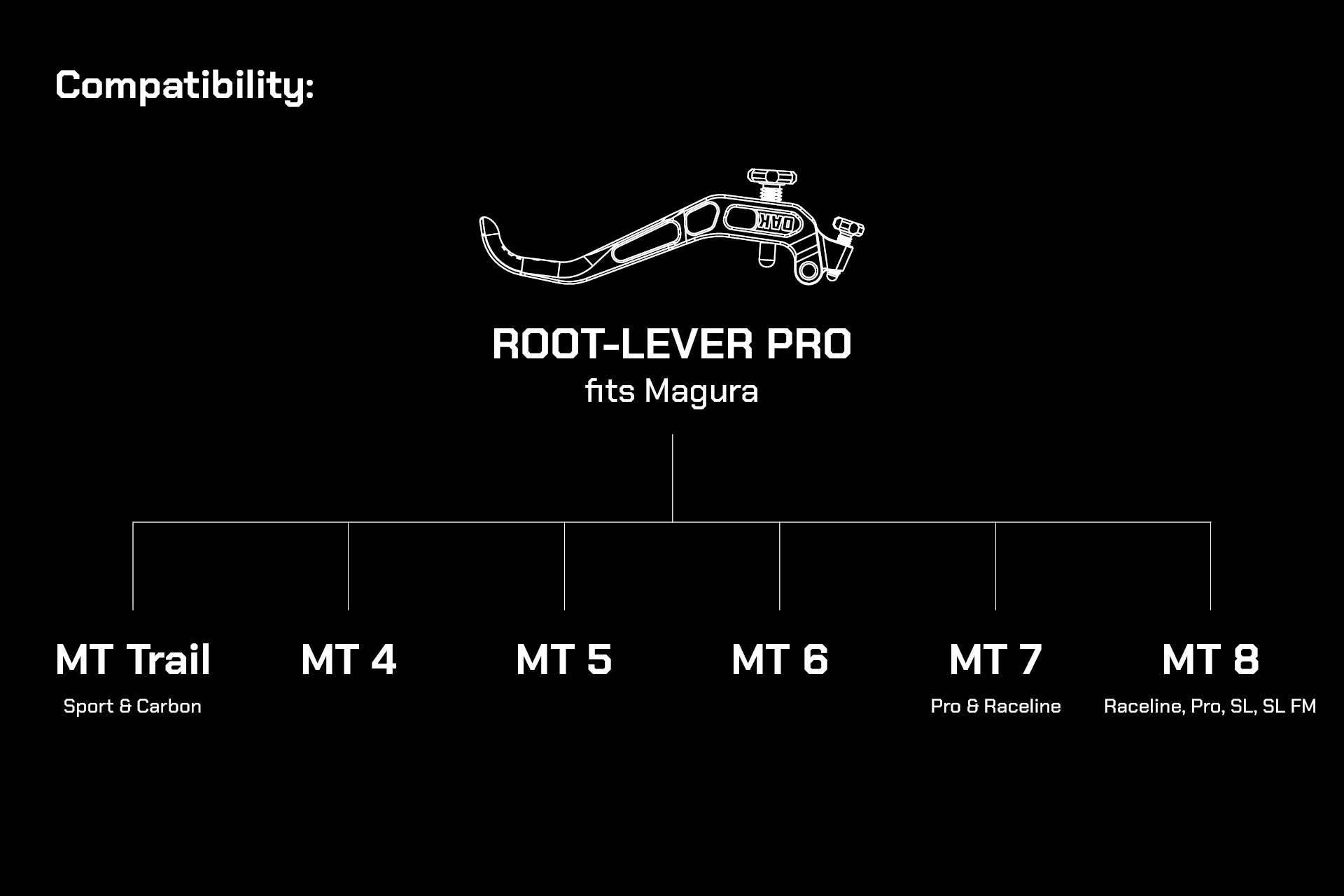

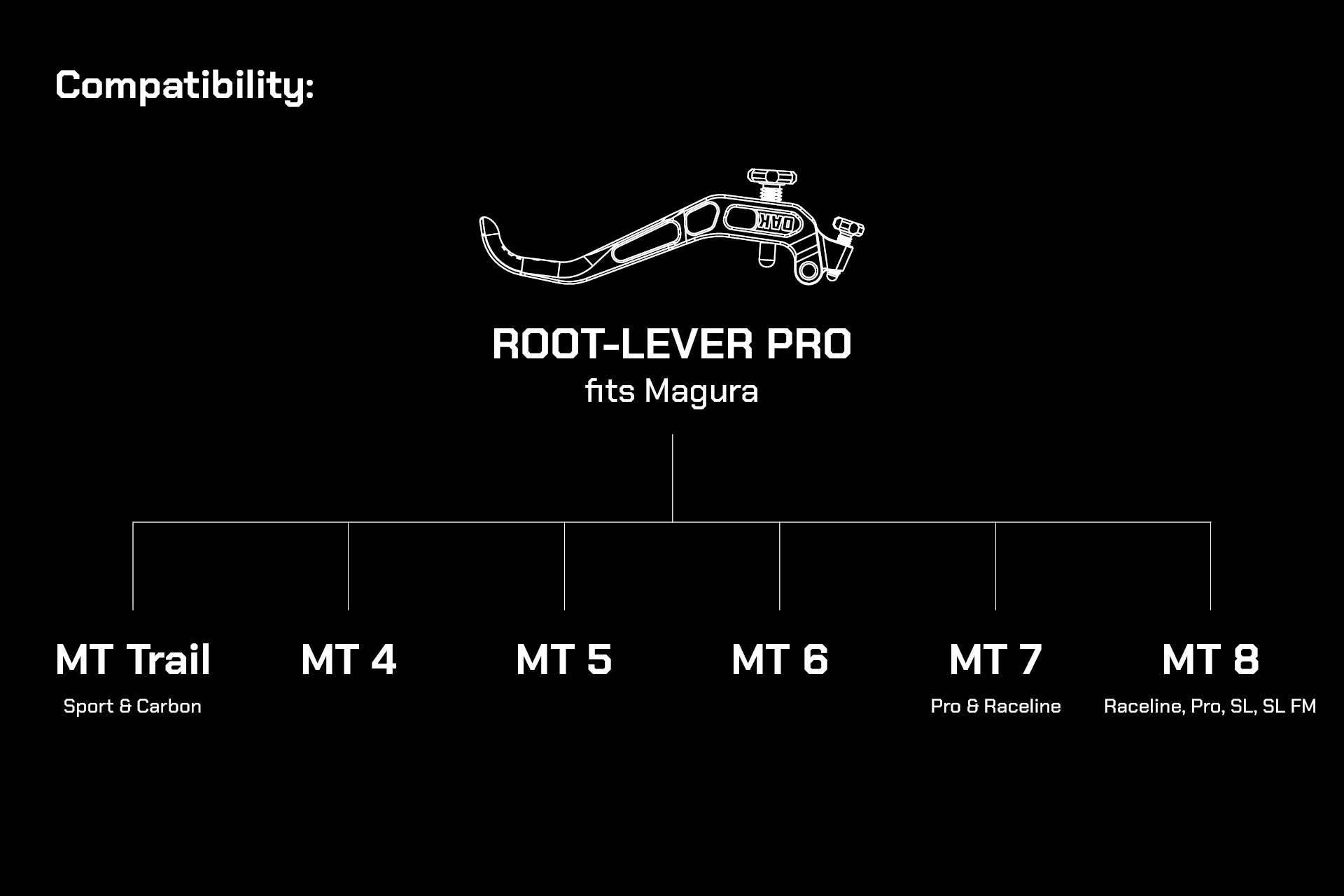

OAK RLP Brake Lever Blade Set - fits Magura

The revolutionary brake lever upgrade for your MAGURA brake system

Impresses with durability, adjustability and unique design.

The optimized mechanical transmission makes your brakes more powerful, easier to control and guarantees incredibly precise braking, thus achieving the highest level of precision.

Crash? No problem! If you manage to break the lever, contact us for a crash replacement.

Secure your advantage on the trail now and become part of the OAK revolution.

Matt Beer

Expert opinion

"I've been a fan of Magura brakes for a long time and adding the Root Lever to the system raised their performance even higher.

This niche product is on par for pricing with Magura's highly adjustable HC3 lever, but provides a more traditional lever shape.

With the Contact Pad Adjustment, you can dial in where you want the brakes to engage on the spot without having to overfill the reservoir and keep that crispy feel for a longer period of use."

Instagram: @mattb33r

From bikers for bikers

Team OAK

Our engineers are dedicated mountain bikers themselves, and their OAK developments maximize the fun and performance of every descent. We incorporate product feedback from customers around the world to ensure we offer the best possible parts.

Feel the difference for yourself, ride after ride!

Intensively tested

In addition to laboratory tests, our professional team riders and engineers test all parts in the most demanding areas of riding bikes.

We got your back

Do you need spare parts or further help? Feel free to contact us at any time, we will help you!

Without compromises

If you are not satisfied, the product can be returned within 30 days.

We have answers to your questions

Yes, because the bending protection must be installed. We have tested intensively how the brake line can be reliably protected.

Plastic and rubber were quickly out of the running. Only the use of a steel spring could distribute the point load over a sufficient area and protect the line in the long term. This means that spongy pressure points or oil leaks from leaky brake lines are a thing of the past.

The Root-Lever Pro uses the sweet spot of braking power and controllability. We get the maximum performance out of your Magura brake system, but manage to provide even more controllability through an optimized lever ratio.

Due to a very large adjustment range, we can optimally cover all conceivable settings with one lever version. We don't like trying many different parts to find the right version. This wastes time and resources. We stick to one option which is guaranteed to be able to do everything!

Our brake lever is designed to be more stable to withstand even the greatest stresses in tough racing use. Due to the exquisite choice of materials and intelligent construction, it is more durable than all its competitors. Guaranteed!

Furthermore, with the Root-Lever Pro you can cover a very large adjustment range with just one lever.

If the stable Root-Lever Pro is actually damaged in a fall, we ask you to contact our customer support.

Please use our warranty and crash replacement form

We know the problem of loose springs from our own painful experience and have therefore developed a system that does not require a return spring at all.

No spring – no problem!

Gear ratio is about 6.5 : 1

Yes, it is absolutely necessary to install the Bending Production. The function of the Root-Lever Pro is only guaranteed if it is supported on this component.

Become part of the OAK revolution

Press reviews

The CPA adjustment dial is the standout feature of this lever. It allows you to fully synchronize the contact point of the brake application—a true revolution. This also means you can adjust the feel of the lever as the brake pads wear. Several other long-time Magura fans were also surprised by the precision of the Root Lever.

What is your personal highlight of your bike of the week?

The overall performance of the bike. I really enjoy riding it, and especially with pain-free wrists and forearms again. It's the sum of the parts that makes it all.